How FORTIFIED Roof™ Sealed Roof Decks May Help Reduce Storm Damage

In the event of a severe storm, a durable roof may help protect against water intrusion at the most vulnerable area of a home. With the frequency and intensity of severe seasonal storms increasing, the stresses on roof assemblies and risk of leaks also increases. Under strong storm conditions roof leaks can cause costly repairs and put belongings inside at risk of water damage.

Whether caused by heavy thunderstorms, damaging winds, or hurricanes, water intrusion through the roof can leave a homeowner out of their home for months or longer while waiting for insurance claims to be filed and repairs to be done.

Building sealed roof decks as part of new construction projects has benefits for builders, too. Sealed roof decks built with integrated sheathing and tape from ZIP System™ building enclosures can help achieve a quick rough dry-in to help interior crews start sooner and also help protect interiors from water damage while a roof may be exposed before cladding.

For more than 20 years, the Insurance Institute for Business & Home Safety (IBHS) has extensively researched and tested what makes a strong roof. A result of this research is the the FORTIFIED Roof™ standard [1], part of IBHS’s FORTIFIED Home™ program, which promotes the use of a sealed roof deck as part of its nationally recognized standards for resilient building.

Resilient construction is designing and building structures that can be easily re-inhabitable after disasters or other setbacks.

A ZIP System™ Roof Assembly, comprised of engineered wood panels with an integrated, water-resistive barrier and advanced acrylic tape, provides a secondary continuous water-resistive barrier on a roof deck that helps prevent water intrusion at panel seams. Let’s break down the difference between traditional roof assemblies and a FORTIFIED Roof™ sealed roof deck further.

How does a sealed roof deck prevent water intrusion?

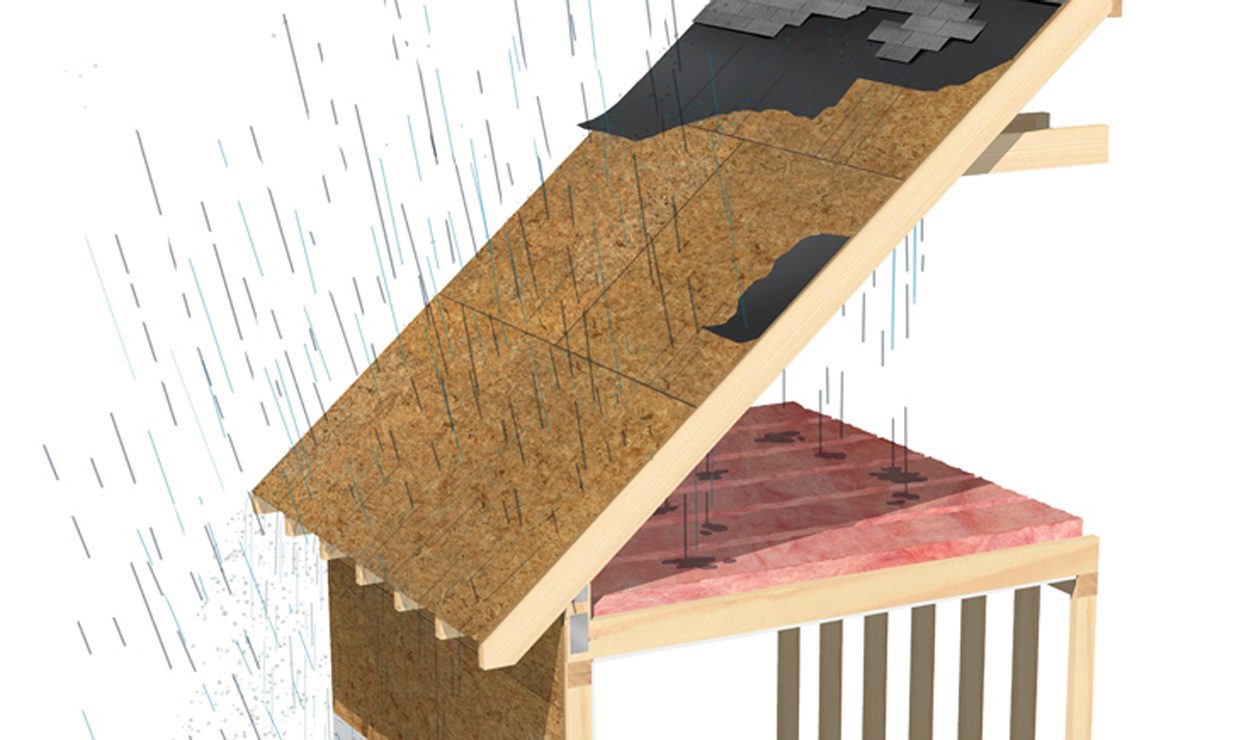

Traditional roof decks may be constructed with oriented strand board (OSB) or plywood panels as the structural sheathing layer. Next, 15lb-30lb felt (per local code) may be installed on top of the panels to repel water off of the wood substrate. Lastly, a roof covering, such as shingles, is attached. In the event the covering, and likely the felt with it, are blown away, this method can leave vulnerable panel seams exposed.

IBHS found that a primary cause of water damage associated with high wind events is that traditional roof assemblies can allow water to flow freely through panel seams when even a portion of the roof covering is damaged. From there, water may either trickle in or pour in with the help of strong, wind-driven rain events.

A sealed roof deck can provide a continuous water-resistive barrier to the roof to help protect the integrity of the structure by sheltering the interior from water damage in the event the roof deck is exposed. This exposure can occur during construction or in a high-wind event if the roof covering is blown off.

A sealed roof deck can reduce water entry by as much as 95% - Anne Cope, Chief Engineer IBHS

“We’ve calculated that an unsealed roof deck allows up to 60% of the rain that hits a damaged roof to enter into the attic. A sealed roof deck can reduce water entry by as much as 95%,” said Anne Cope PhD, P.E., chief engineer for IBHS. “If all the shingles came off a 2,000-square-foot unsealed roof, up to 750 gallons of water could enter the attic for every inch of rain that falls – equivalent to nine bathtubs full of water.”

There are four methods IBHS approves for installing a sealed roof deck to FORTIFIED Roof™ standards:

- Using tape and underlayment, which requires a certain tape and underlayment material applied directly to the roof deck.

- Applying a full layer of self-adhering membrane to the roof deck.

- Installing two layers of felt underlayment to the roof deck.

- Applying spray foam on the underside of the roof at every joint and seam.

Using Integrated Sheathing to Install Sealed Roof Decks More Easily

ZIP System™ Roof Assembly is a streamlined approach to a sealed roof deck using tape and underlayment because of its integrated sheathing and tape design. Each ZIP System panel comes with a built-in, weather-resistive underlayment, and when seams are sealed with ZIP System flashing tape, it creates a continuous water-resistive barrier that eliminates the need for additional felt or self-adhered membranes to meet FORTIFIED Roof™ guidelines for a sealed roof deck.

This assembly also provides a continuous rigid air barrier by design, which reduces air leakage and can contribute energy efficiency benefits if the roof is built over a conditioned attic space.

Using this streamlined approach to a sealed roof deck with ZIP System sheathing and tape not only helps keep the water out in a high-wind, wind-driven rain event, but also helps achieve a quick rough dry-in, which can help interior crews start work sooner.

Utilizing these integrated products to create a sealed roof deck means the structural panel, underlayment and air barrier are all warranted under a single manufacturer, too. You can learn more about the terms and conditions of the ZIP System Roof Assembly 30-year Limited Warranty and 180-Day Exposure Guarantee here.

ZIP System Roof Assembly is the first manufacturer-warranted integrated roof panel and tape system that meets the sealed roof deck standards for a FORTIFIED Roof™.

Benefits of a Sealed Roof Deck in a Hurricane-Force Test

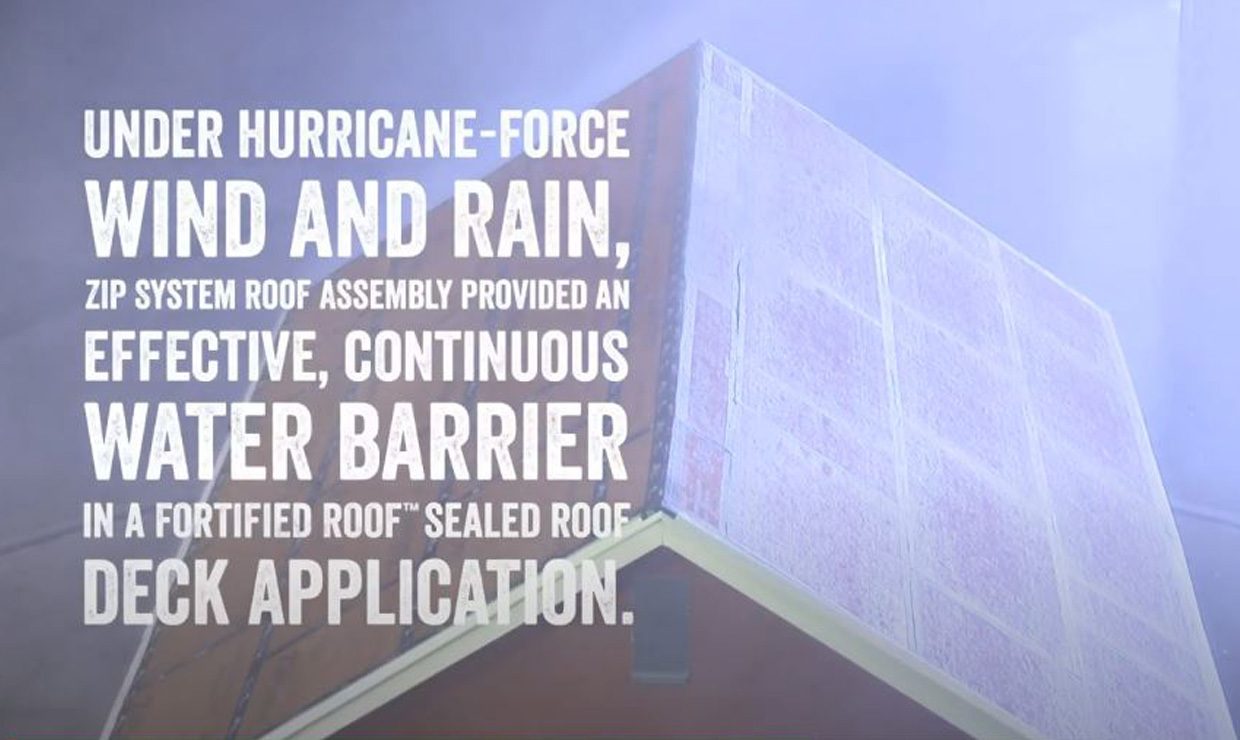

IBHS recently put sealed roof deck standards to the test, conducting a hurricane-force, wind-driven rain demonstration to show the water resistance of a FORITIFED Roof™ sealed roof deck built with a ZIP System™ Roof Assembly.

In the demonstration, 105 fans reaching peak speeds of 105 mph and a rainfall rate of 8 inches per hour were released onto a model house outfitted with a ZIP System Roof Assembly.

The wall of fans was programmed to provide gusts and triangulation of wind to replicate wind trace data collected during Hurricane Florence in North Carolina. The sealed roof deck built with ZIP System® sheathing and tape was 830 square feet and faced over 2,000 gallons of rain in 30 minutes, equating to about 4 inches during the 30-minute demo.

The resulting well-protected interior with a dry attic demonstrated that ZIP System Roof Assembly provides an effective water-resistive barrier even when completely exposed during Category 1 hurricane conditions.

Under a punishing wind-driven rain, ZIP System really delivered a sealed roof deck solution - Kurt Koch VP Product Engineering and Quality for Huber Engineered Woods

“The rain downpours and wind gusts simulated those that occurred during Hurricane Florence,” said Kurt Koch, VP Product Engineering and Quality for Huber Engineered Woods. “Under a punishing, realistic period of high wind and wind-driven rain, ZIP System Roof Assembly really delivered as a sealed roof deck solution.”

Discover more from ZIP System Roof Assembly at TrustZIPRoof.com.

The IBHS mission is to conduct objective, scientific research to identify and promote effective actions that strengthen homes, businesses and communities against natural disasters and other causes of loss. Explore more about what IBHS is doing to create safer, more durable homes at DisasterSafety.org.

© Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.